Production enforce standard

| Product specification | Design spec | Face to face | Flange end | Pressure-temp | Test&check |

| API 6D API 600 API 603 |

ASME B16.10 API 6D | ASME B16.5 RF | ASTM B16.34 | API598 |

Material of Main Parts

| Name | Body | Disc | Seat | Stem | Handwheel |

| Material | ASTM A216 WCB | ASTM A216+13CR | ASTM A216+13CR | ASTM A276 420 | ASTM A47 |

| Material | ASTM A 351 CF8 | ASTM A 351 CF8 | ASTM A 351 CF8 | ASTM A182 F304 | ASTM A47 |

Technical Data

| Nominal Pressure | 150Lb(2.0MPa) | 300Lb(5.0MPa) | 600Lb(10.0MPa) | 900Lb(15.0MPa) | Test Medium |

| Shell Test | (3.0MPa) | (7.8MPa) | (15.0MPa) | (22.5MPa) | Water |

| Seal Test | (2.2MPa) | (5.6MPa) | (11.0MPa) | (16.5MPa) | |

| Back Seal Test | (2.2MPa) | (5.6MPa) | (11.0MPa) | (16.5MPa) | |

| Air SealTest | 80Lb(0.6MPa) | 80Lb(0.6MPa) | 80Lb(0.6MPa) | 80Lb(0.6MPa) | Air |

| Suitable Temp | -29~425°C | ||||

| Suitable Media | Water/Steam/Oil | ||||

150LB

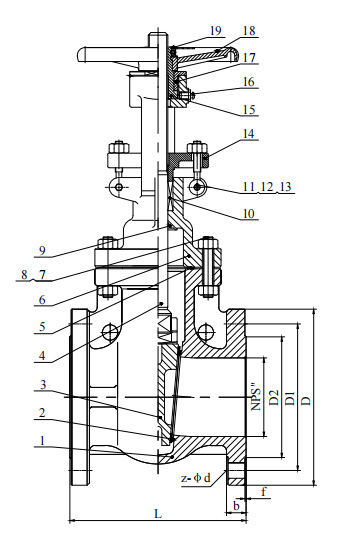

| NPS | DN | L | D | D1 | D2 | b | z-d | f |

| 1/2" | 15 | 108 | 89 | 60.5 | 35 | 11 | 4-15 | 2 |

| 3/4" | 20 | 117 | 98 | 70 | 43 | 11 | 4-15 | 2 |

| 1" | 25 | 127 | 108 | 79.5 | 51 | 11 | 4-15 | 2 |

| 1 1/4" | 32 | 140 | 117 | 89 | 64 | 12.8 | 4-15 | 2 |

| 1 1/2" | 40 | 165 | 127 | 98.5 | 73 | 14.3 | 4-15 | 2 |

| 2" | 50 | 178 | 152 | 120.5 | 92 | 16 | 4-19 | 2 |

| 1 1/2" | 65 | 190 | 178 | 139.5 | 105 | 17.5 | 4-19 | 2 |

| 3" | 80 | 203 | 190 | 152.5 | 127 | 19 | 4-19 | 2 |

| 4" | 100 | 229 | 229 | 190.5 | 157 | 24 | 8-19 | 2 |

| 5" | 125 | 254 | 254 | 216 | 186 | 24 | 8-22 | 2 |

| 6" | 150 | 267 | 279 | 241.5 | 216 | 26 | 8-22 | 2 |

| 8" | 200 | 292 | 343 | 298.5 | 270 | 29 | 8-22 | 2 |

| 10" | 250 | 330 | 406 | 362 | 324 | 31 | 12-25 | 2 |

| 12" | 300 | 356 | 483 | 432 | 381 | 32 | 12-25 | 2 |

| 14" | 350 | 381 | 533 | 476 | 413 | 35 | 12-29 | 2 |

| 16" | 400 | 406 | 597 | 540 | 470 | 37 | 16-29 | 2 |

| 18" | 450 | 432 | 635 | 578 | 533 | 40 | 16-32 | 2 |

| 20" | 500 | 457 | 698 | 635 | 584 | 43 | 20-32 | 2 |

300LB

| NPS | DN | L | D | D1 | D2 | b | z-d | f |

| 1/2" | 15 | 140 | 95 | 66.7 | 34.9 | 14 | 4-16 | 2 |

| 3/4" | 20 | 152 | 115 | 82.6 | 42.9 | 16 | 4-19 | 2 |

| 1" | 25 | 165 | 125 | 88.9 | 50.8 | 17.5 | 4-19 | 2 |

| 1 1/4" | 32 | 178 | 133 | 98.5 | 63 | 19 | 4-19 | 2 |

| 1 1/2" | 40 | 190 | 156 | 114.5 | 73 | 21 | 4-22 | 2 |

| 2" | 50 | 216 | 165 | 127 | 92 | 22 | 8-19 | 2 |

| 1 1/2" | 65 | 241 | 190 | 148 | 105 | 25 | 8-22 | 2 |

| 3" | 80 | 282 | 210 | 168 | 127 | 29 | 8-22 | 2 |

| 4" | 100 | 305 | 254 | 200 | 157 | 32 | 8-22 | 2 |

| 5" | 125 | 381 | 279 | 235 | 186 | 35 | 8-22 | 2 |

| 6" | 150 | 403 | 318 | 270 | 216 | 36.6 | 12-22 | 2 |

| 8" | 200 | 419 | 381 | 330 | 170 | 41 | 12-25 | 2 |

| 10" | 250 | 457 | 444 | 387.5 | 324 | 48 | 16-29 | 2 |

| 12" | 300 | 502 | 521 | 451 | 381 | 51 | 16-32 | 2 |

| 14" | 350 | 762 | 584 | 514.5 | 413 | 54 | 20-32 | 2 |

| 16" | 400 | 838 | 648 | 571.5 | 470 | 57 | 20-35 | 2 |

| 18" | 450 | 914 | 711 | 628.5 | 533 | 60 | 24-35 | 2 |

| 20" | 500 | 991 | 775 | 686 | 584 | 64 | 24-35 | 2 |

1.Casting

2.Processing

3. Assemble

4. Test

5. Spray paint

6. Inspection